CAESAR II piping stress analysis

The Fiber Glass Systems Engineering Services Team in Plymouth has a long and broad experience in providing static and dynamic analysis in pressure systems for thermoplastic, thermosetting (GRE) and metallic piping for suspended, buried, marine, industrial and offshore applications.

In combination with CAESAR II, the most widely used pipe flexibility and stress analysis software, we carry out detailed piping stress analysis, evaluating and confirming structural and operational integrity of process piping systems to ensure compliance in accordance with international piping codes and standards ISO14692, B31.3, UKOOA, BS7159, API610 and AWWA.

Technical specification:

- International piping code database

- Automatic stress isometric creation

- Material physical and mechanical property database

- Hanger design and database

- Expansion joint database

Key features/benefits:

Structural Integrity

- Design adequacy for the pressure of the carrying fluid

- Failure against various loading in the life cycle, limiting stresses below code allowable

Dynamic & Seismic Analysis:

- Utilising CAESAR II dynamic module, we can carry out checks for earthquake effect and natural frequency of the system to ensure integrity through the design life

Operational Integrity

- Limiting nozzle loads of the connected equipment within allowable values

- Avoiding leakage at joints

- Limiting sagging & displacement within allowable values

Optimal Design:

- Avoiding excessive flexibility and high loads on supporting structures

- Optimal designs for both piping and structures

Support Verification:

- Selection of optimal spring hangers if required

- Evaluate support lift off, friction and gap closure

For more information on how you can fully utilize our engineering services & capabilities, get in touch now.

Project examples:

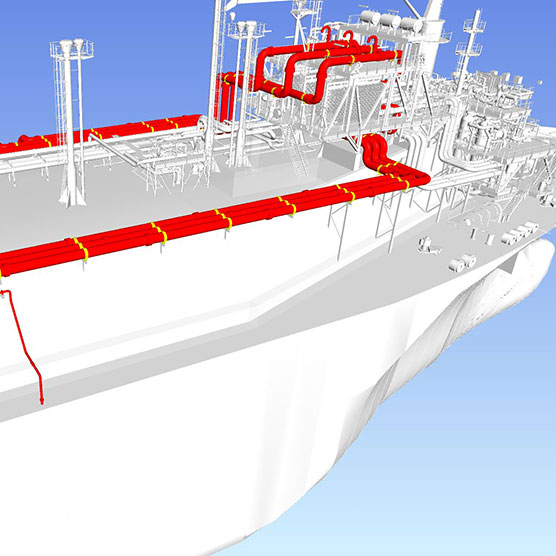

BW Fleet Suez Paris FPSO – Topside sea water pump cooling system stress and support verification to ISO14692 for a 30” 7000M marine pipe series. Hull deflections, equipment nozzle loads, and support load verification for a complete package.

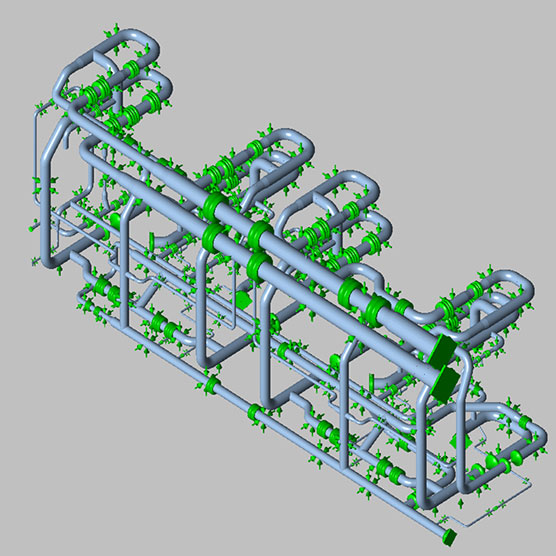

ADMA-OPCO Zakum fine filter skid – Stress code compliance to ISO14692 for suspended BONDSTRAND® 7000M up to 14” diameter including support design, equipment nozzle checks and surge loads from the hydraulic analysis.

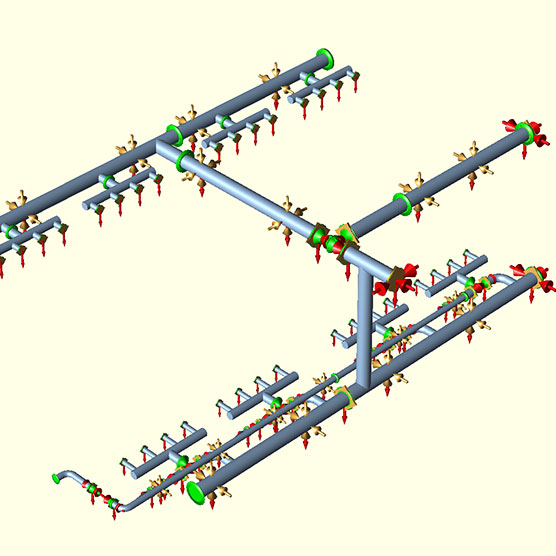

BP Sullom Voe Terminal fire main – Stress code compliance to ISO14692 for new buried 24” BONDSTRAND® 2416C main with valve chambers and tie-ins to existing including surge loads from the hydraulic analysis; road crossings to AWWA M45.

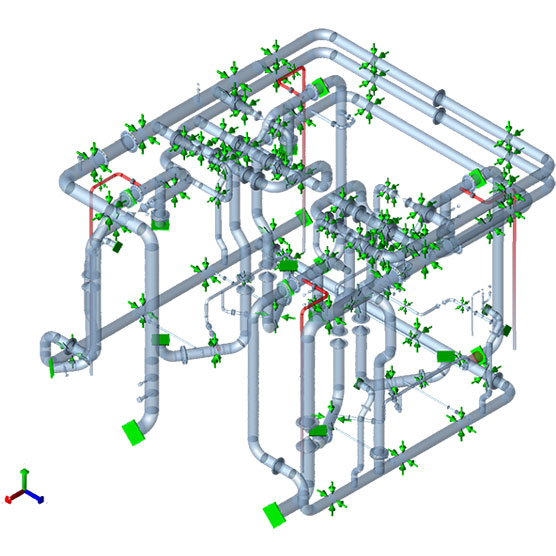

Sete Energy Saudia H2S Stripping Package – Stress code compliance to B31.3 for various ASTM A-106 steel lines and UKOOA code compliance for BONDSTRAND® 2414 lines up to 10” including support design and equipment nozzle checks.

TOTAL Clov FPSO Headers– static analysis to ISO 14692 of 40” & 30” large diameter BONDSTRAND® 2425C headers for Mahle Industrial Filtration including support design and equipment nozzle checks.

Shell Prelude Floating LNG – Topside tank ducting stress code compliance to UKOOA for 18” BONDSTRAND® 2416C and ASME B31.3 for 18” 316L stainless steel including hanger support design, incorporating topside structural displacements, hull deflections and accelerations for operational and towing conditions.