Project Overview:

The White Cart Viaduct, located in Scotland, is an elevated section of the M8 and is recognised as one of the busiest routes in the country. It currently carries over 95,000 vehicles a day across the White Cart River, and therefore systematic corrosion inspections, especially of the viaduct’s beams, is imperative.

Requirement: Safe access for maintenance teams to reach and perform inspection checks 21 metres from ground level, above a river.

Problem: Extremely restricted site access, unsuitable for crane operation. Additional structure would require fixing to existing framework.

Solution: A bespoke Fibre Reinforced Polymer (FRP) access structure designed and manufactured by experts.

Fiber Glass Systems successfully designed, supplied and fabricated a 76 metre FRP maintenance and inspection walkway for the underside of the viaduct, complete with access landing platforms and stairs.

Our in-house Engineering Services Department (ESD) carried out detailed design of the modular FRP suspended walkways, end landings and access staircases. They were also able to develop all metallic fixtures and connections required to safely secure the FRP structures to the underside bridge support. The design was completed by hand calculations and verified by an independent third party CAT III checker.

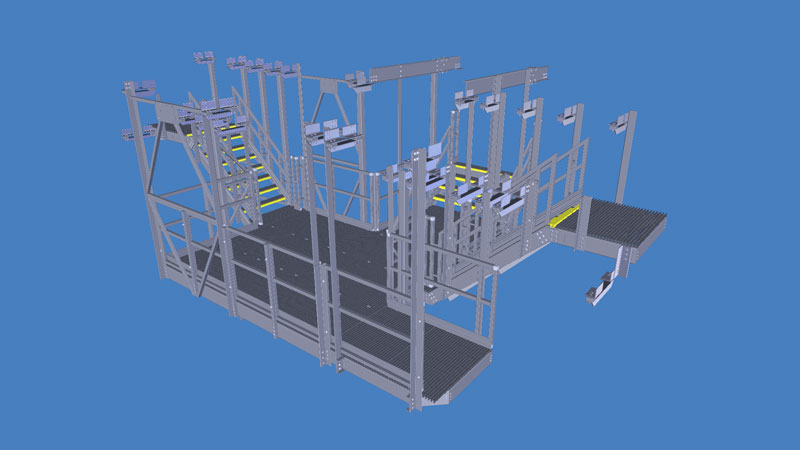

Image (Parametric 3D model of staircase interface module)

This bespoke walkway was prefabricated at our manufacturing facility and delivered to site in modular sections;

- Main walkway module – 2.2 metres wide x 3 metres long

- Secondary walkway – 1.2 metres wide x 1.8 metres long

- Access landing Platforms – 1.3 metres wide x 1.7 metres long

- Main end landing platforms – 3.3 metres wide x 4 metres long

Our FRP structural solutions typically weigh 1/3rd that of comparative steel structures, enabling ease of construction at the heights required – without the use of cranes! Roped access techniques were employed to position the modules safely in place before clamping onto existing cross girders.

- Other project advantages included;

- Lightweight FRP minimising load on the main bridge structure

- Little or no maintenance requirement during 60+ year design lifespan

- Extreme corrosion resistance

- Low weight, resulting in low installation costs

Image (Photo(s) courtesy of MHB Consultants www.mhbconsultants.com.).

If you need a weight saving, corrosion resistant and low maintenance solution, why not consider FRP? Contact us now to find out more at [email protected].

![[Main]-Whitecart-site](https://pipexltd.com/wp-content/uploads/2019/04/Main-Whitecart-site.jpg)