Fiber Glass Sytems are recognised globally as true innovators in Fibre Reinforced Polymer (FRP) composite advanced design and manufacture.

Our facility in Plymouth, Devon is home to the Resin Infusion Centre of Excellence (R.I.C.E) which houses one of the UK’s largest 5 axis CNC machines (designed and built by our inhouse experts) fully supported by a world class Engineering Services team.

With our unique design and manufacture capabilities we are able to provide our clients with a complete problem solving solution from a single source.

One of our specialities is ground breaking FRP Composite Bridge design and build, a recent project example of which is the Dover Sea Wall replacement footbridge, situated in Kent.

During severe storms on Christmas Eve 2015, the Dover Seawall, together with 250 metres of track, collapsed. The devastation was considerable and this major coastal rail-line and steel footbridge were subsequently condemned.

As part of a £39.8 million reconstruction project we were asked to design and fabricate two 14.5 metre long FRP composite pedestrian footbridges together with connecting staircases and landings.

The footbridges were designed by our team of Engineers and included advanced laminate Finite Element Analysis (FEA) supported by hand calculations and testing. All designs had to be fully compliant with Network Rail rigorous standards for footways situated over live railway tracks, together with CAT III checking by a third party before acceptance by Network Rail.

Many additional features were introduced on this project including;

- Phenolic wear plates – providing an anti-slip surface for pedestrians

- Spray finished in Moss Green as per client specifications

- Bridge soffit fitted with 42 pressure sensors to enable the testing of train buffeting in conjunction with the dynamic response (be sure not to miss coverage of this ground-breaking testing in our news section over the coming months)

- Design life of 120 years

In addition to our advanced design and manufacture capabilities, our comprehensive in-house testing and installation resources enabled us to complete a FULL trial assembly at our Plymouth facility. Further testing included a water fill test simulating Serviceability Limit State (SLS) conditions together with a lateral wind load test, ensuring the complete safety and quality of the structure prior to installation on site.

We utilised our 24/7 production capability to fabricate two FRP footbridges, together with all associated staircases and landings, each footbridge measured 14.5 metres and weighed 4.5 tonnes. The final completed structure measured an impressive 2.415 metres wide x 3.372 metres high x 31 metres long.

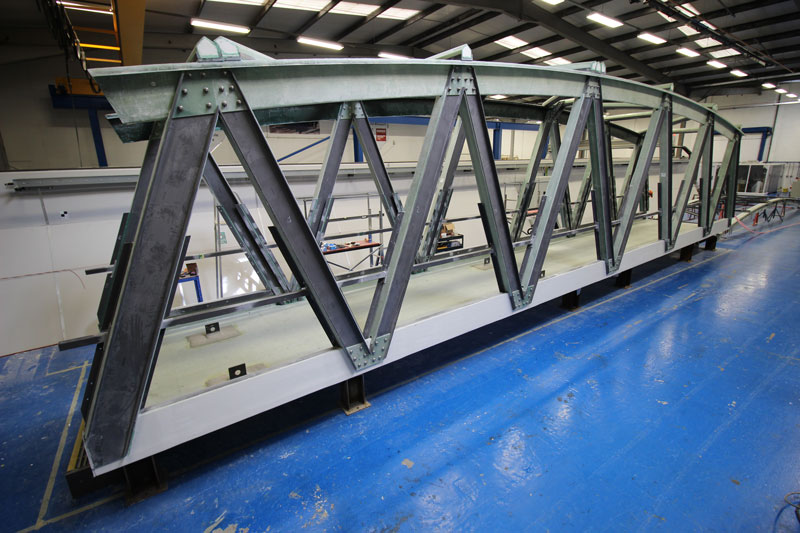

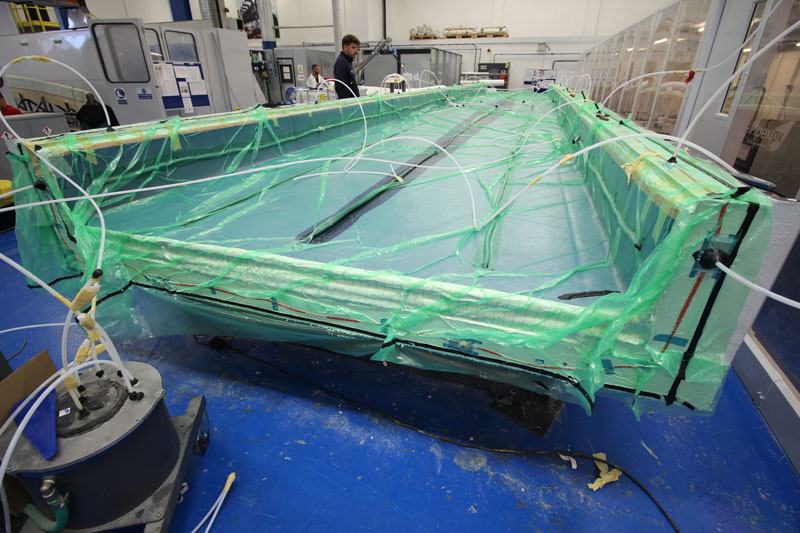

Both footbridges were manufactured from a hybrid of pultruded and resin-infused components for optimum strength, all of which were designed by our Engineers. The bridge deck, top cords and anti-slip phenolic wear plates were resin-infused completely in-house, together with all the required tooling; FRP moulds, plugs and precise bolt hole patterns i.e. node connections.

Due to our innovative facilities we were able to CNC these vital components on our 30m long x 7m wide x 6.25m high 5-axis CNC machine – further ensuring a high build tolerence. The truss members, stairwells, landings and parapet panels were manufactured from FRP pultruded sections and plates. Images below show the bridges during the various manufacturing stages within the R.I.C.E. facility.

Fiber Glass Systems provided an expert installation team throughout the installation phase to ensure extremely costly possession times were minimalised as much as possible for our client. This included a particularly windy and wet New Year’s Eve!

This flagship project is the largest resin-infusion completed to date in our R.I.C.E. facility.

Installation of the footbridge is now complete and due to be opened for public access during Spring 2017. Watch for yourself how this engineering feat was accomplished in our time-lapse video.

For more information on how our array of design and build capabilities could be benefiting your projects, contact us now at [email protected] or telephone 01752 581200 to speak with one of our friendly experts.

![[Main]-PSC9826-Dover-Sea-Wall-Footbridge-(35)1-(1280x720)](https://pipexltd.com/wp-content/uploads/2019/04/Main-PSC9826-Dover-Sea-Wall-Footbridge-351-1280x720.jpg)