The North West’s largest waste water treatment works (WWTW), located in Manchester, handles flows reaching in excess of 30,000 litres per second during heavy rainfall and handles everything flushed away by 1.2 million people!

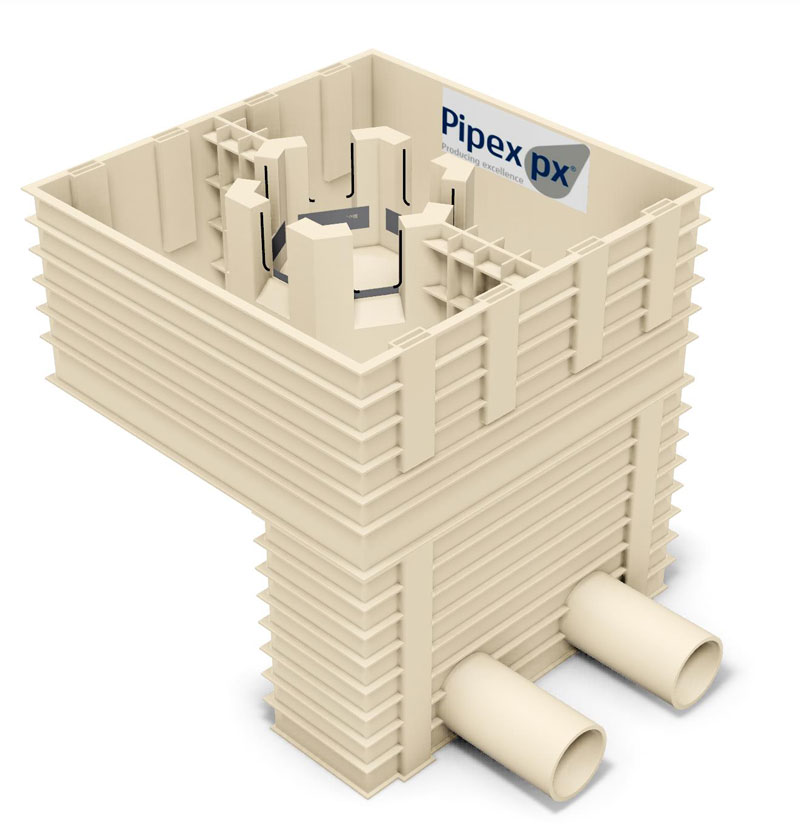

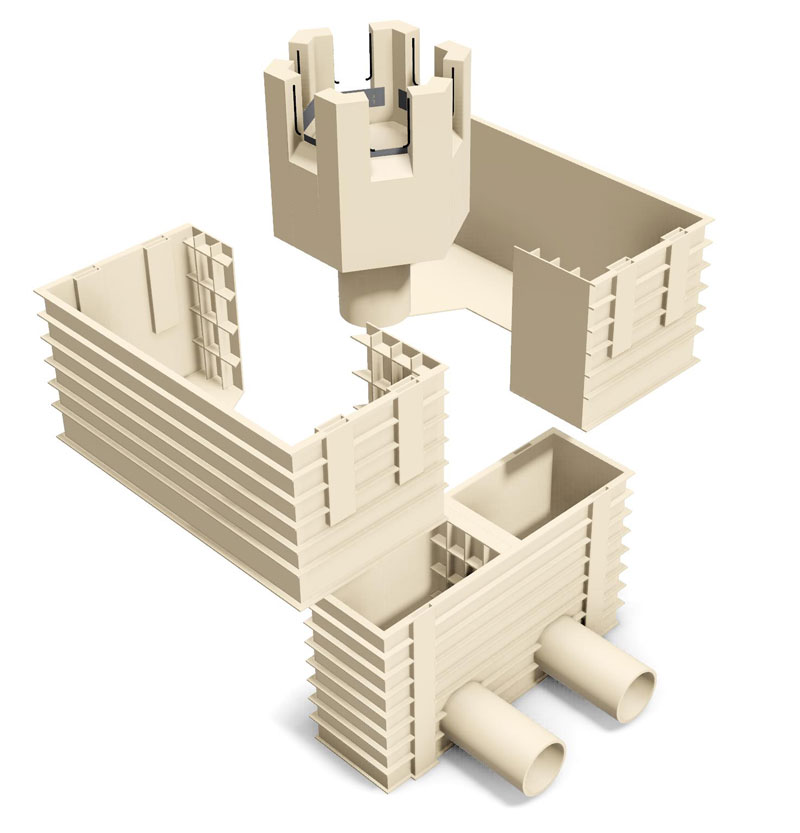

Fiber Glass Systems supplied and fabricated two bespoke chambers for this project, 1x flow splitter chamber and 1x sump chamber designed to assist with directing the flow of excess waste water, dampening the flow for distribution into the sewage treatment works.

Due to the complex nature of both design and shape, these chambers are difficult to build using traditional materials such as concrete.

However, we were able to provide our clients with Design for Manufacture (DfM) solutions using the highly corrosion resistant and lightweight modern thermoplastic material, High Density Polyethylene (HDPE).

This advanced material offers a greater level of design flexibility and also allows for off-site build – minimising both the installation time required on site and project safety risks.

The flow splitter chamber was manufactured in two sections, measuring a total of 5.4m long x 5.4m wide x 2.8m high and was delivered to site complete with internal weir & weir plates, factory fitted rebar reinforcement and our composite grey shuttering.

The sump chamber (image right) was 5.4m long x 1.55m wide x 3.2m high and included internal benching, plain spigot outlets, steel rebar reinforcement and timber shuttering.

Both chambers, together with all the additional internal components and reinforcement, were fabricated at our advanced manufacturing facility based in Plymouth. Once delivered to site our lightweight, off-site build chambers were able to be dropped into position and allowed for immediate concrete pour.

For more information on our off-site built civil engineered solutions please contact our Technical expert, [email protected] or call us on 01752 581200.

![[Main]-PDC9852-Davyhulme-STW-Storm-Splitter-Chamber-(120)](https://pipexltd.com/wp-content/uploads/2019/04/Main-PDC9852-Davyhulme-STW-Storm-Splitter-Chamber-120.jpg)