In November 2011 the Chancellor announced that, as part of 6 UK growth schemes, the M3 Junction 2 to 4a would be upgraded to a smart motorway. Smart motorways are designed to ease congestion by using technology to fluctuate speed limits in line with traffic demands. In the case of the M3, the hard shoulder will be converted into a “running lane”, creating additional capacity without the need for more expensive road widening.

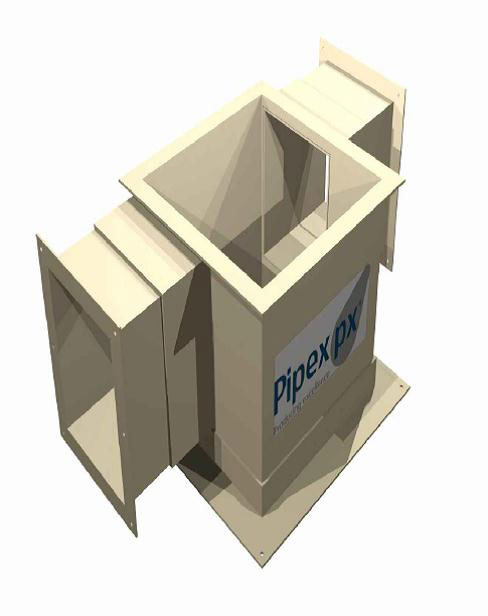

When constructing the central reservation barrier on motorways, drainage is a key aspect of consideration and one for which Fiber Glass Systems® 40+ years of experience and advanced thermoplastic solutions are ideally suited. We have the in-house capability to detail design the solutions using our BIM software and experienced design and CAD teams. Our factories have advanced tooling and bespoke equipment which is designed and built in-house to efficiently and quickly manufacture the units and deliver to site to allow fast track installation.

Due to the success of our previous motorway projects, including the M25, we were appointed to supply, fabricate and deliver;

- 720 Linear Drainage Outfall (LDO) Chambers

- 1440 LDO PP-H Top Hats

- 720 LDO Chamber Top Hats

- 40 Hexagonal PP-H Top Hats

All units were manufactured from Polypropylene (PP-H), of bespoke design and adhered to clients’ requirements, their material of manufacture offered a host of advantages to this large-scale project including;

- Extreme corrosion resistance

- Virtually maintenance free

- Lightweight

- Fast track installation

- Reduction in possession times

For more information on how we installed a 12.5M chamber on a busy junction in Manchester in just ONE DAY, keeping traffic disruption to a minimum email us at [email protected].